Mainly engaged in the processing of various precision spring and sheet metal, precision stamping parts, as well as the design and development of precision molds

Our customer is the core of our quality guidance. We produce high-quality products using an advanced quality management system based on data and process flow, together with high-precision tests and inspections.

●We have passed and acquired ISO 9001:2015, IATF 16949:2016, ISO14001 environment management system standard certification, and implemented IECQ-QC080000(RoHS), OHSAS18001 management system. We have established an excellent systematic quality management system. We have established an excellent systematic quality management system.

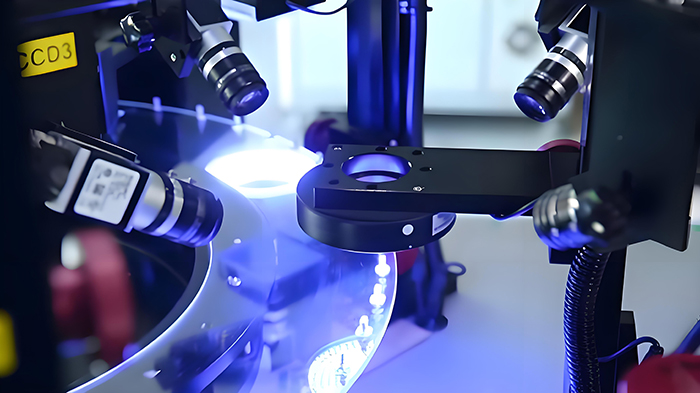

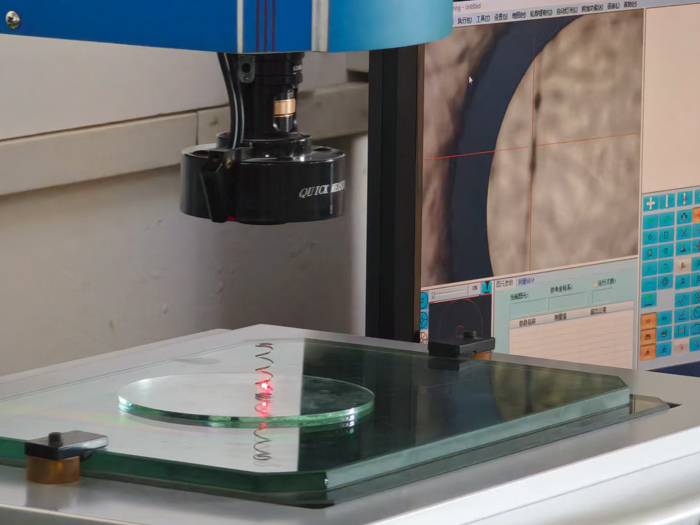

● We have invested in high-precision testing equipment and multi-function testing equipment to enable full coverage of the product with zero blind spots, from raw material, prototype, process product, and mass-produced product. We perform 100% inspection of key dimensions to fully ensure our product quality.

● We have established an industrial advanced-level inspection and test centre. We create customized full-process quality control inspection and test solutions, hence we achieve full process control and quality data traceability of the product life cycle, from raw material, prototype, process product and mass-produced product.

● It is the consensus of all employees to insist that high-quality products are the result of manufacturing rather than inspection. We continuously improve the product process to improve the quality, constantly optimize foolproof measures, and strive for excellence. The production capacity of product characteristics and required dimensions usually reach and pass CPK ≥ 1.67, exceeding the expectations of most customers.

● Corrective and preventive measures (CAPA) shall be taken in time for problems in the production process, and active prevention shall be carried out in parallel and horizontally. All suspected products shall be treated as unqualified products, to effectively ensure the product quality.

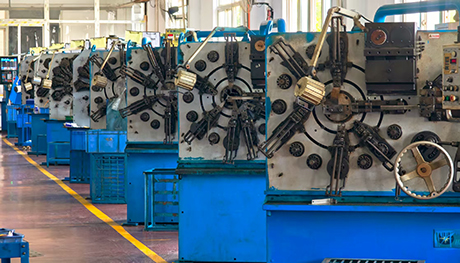

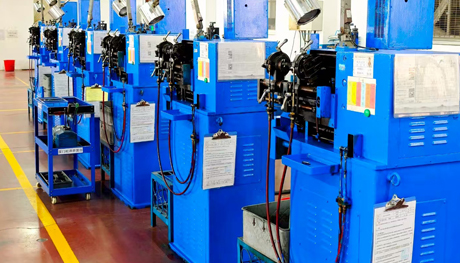

Equipment

Our company not only has several computer machines, compression spring machines, torsion spring machines, forming machines, etc., and other high-precision production equipment but also has several wire cutting machines, grinders, material levelling machines, heat processors, ultrasonic cleaning machines, riveting machines, optical image inspection machines, multiple axes tapping machine and other auxiliary equipment for subsequent work provide enhanced guarantee for the high quality of products

Spring equipment: Machinable wire diameter: 0.06mm-6.0mm

Balance bar equipment: Machinable wire diameter: 0.25mm-2.0mm

Stamping equipment: machinable material thickness is 0.05mm-10.0mm, die length is less than 1.5m, and die processing accuracy is less than 0.003mm

Testing

Our company not only own several optical image measuring instruments, tensile pressure testing machines, torsion testing machines, X-ray fluorescence spectrometers, constant temperature and humidity machines, fatigue testing machines, salt water spray testing machines, microscope, high-definition image magnifying glasses and other testing equipment but also has several self-made inspection and treatment tools so that the size and function of products can be inspected from raw materials to factory inspection, production process control. The testing equipment allow us to check at all product life cycle stages, enhancing and guaranteeing the product through the full use of inspection and testing facilities.

Original and customized built special fixture for testing

100% inspection for key dimensions

Reduce the detection error and fully ensure the quality of each product